News

Beritech invests again; newest addition in the field of sheet metal cutters’

Beritech invests again; newest addition in the field of sheet metal cutters’

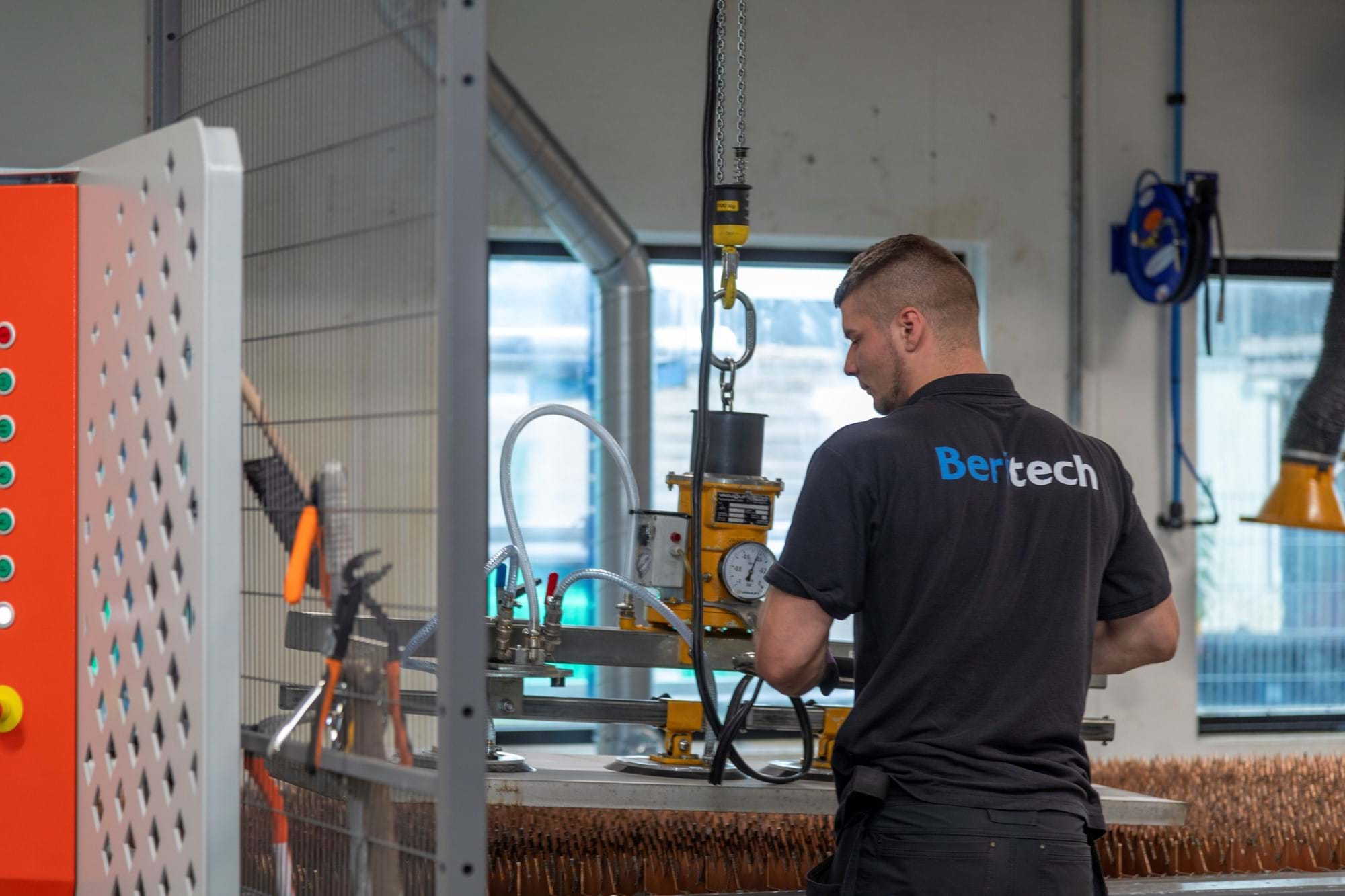

It has been a good year of growth for Beritech, which has resulted in investments in both new machines and more employees.

In 2022 Beritech have invested large amounts totalling millions within new machines and robot technology with the purpose to cover an increasing request for sustainability and effective solutions. Most recently the cutting department at Beritech, recieved the new Bystronic 15kW fiber laser cutting machine.

Perfect cut and automation

On average, thanks to the new 15 kW laser, the cutting speed increases by up to 50 percent compared to 10 kW laser source, which means that Beritech and their clients can benefit from higher productivity with lower unit costs.

The expensive machine is equipped with the latest fiber technology and kerf scan, which results in consistent cutting quality over the entire plate. The machine is equipped with Bytrans Extended which enables unmanned operations with automatic filling and waste management. Fully automatic nozzle changing system increases the radiation time, as several types of sheets can be loaded into the magazine for large series productions.

With the ultramodern equipment the new fiber laser cutter has become the most powerful machine in Beritech’s cutting department, which indicates a lot.

“It is not only a question about whether we’re able to be more productive and reduce our expenses. The new laser effect is truly a gamechanger we’ve been waiting for in this industry” explains Steen Buus Christensen, Sales Manager at Beritech Manufacturing.

He explains this is due to the technology’s many obvious advantages.

“In the past sheets above a certain thickness would’ve been cut with water cutting or plasma cutting, depending on the sheet’s further use. This machine can do anything, as it’s able to deliver both great cutting results which we know from the water cutting and its high volume knowned from plasma cutting,” says Steen Buus Christiensen.

Benefits clients for both semifinished and finished products

The new machine, which just has been installed, provides great benefits in sight for the clients.

Beritech Manufacturing provide services to clients within both single steel processing and turnkey production. The new plate cutter will therefore be used both for semifinished and finished products. Beritech have already received inquiries in both small and large series production with plate processing from clients who’s outsourcing plate cutting. The machines will also have to cut sheets for further processing at Beritech. For instance, it can be used for the production of lifting equipment for the food industry which requires sheets cutting up to 40 mm. stainless.

“This new machine ensures us a strong position on the market. We are looking towards a new year with a record number of orders and we’re still undertaking larger and more complex tasks. With this new machine can we handle even more assignments within sheet metal cutting both when we’re providing service to our clients with individual processes and clients with turnkey production,” Steen Buus Christensen explains.