From Global Visions to Microscopic Precision.

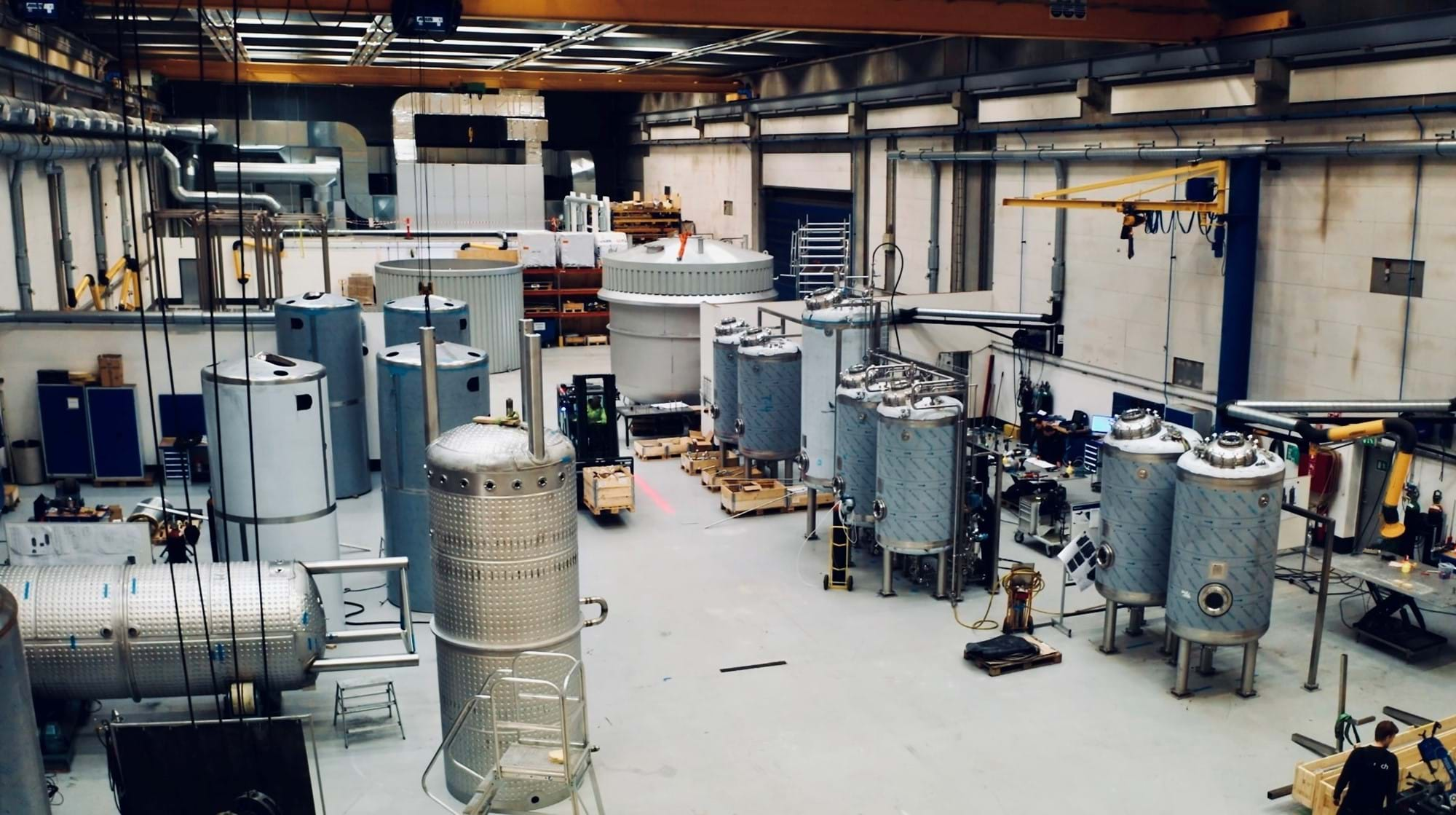

Beritech specializes in designing, manufacturing, and implementing high-quality process equipment for the pharmaceutical industry.

Our core mission is to support the success of clients with tailored solutions that meet the strictest industrial standards, enhancing the efficiency of production processes.

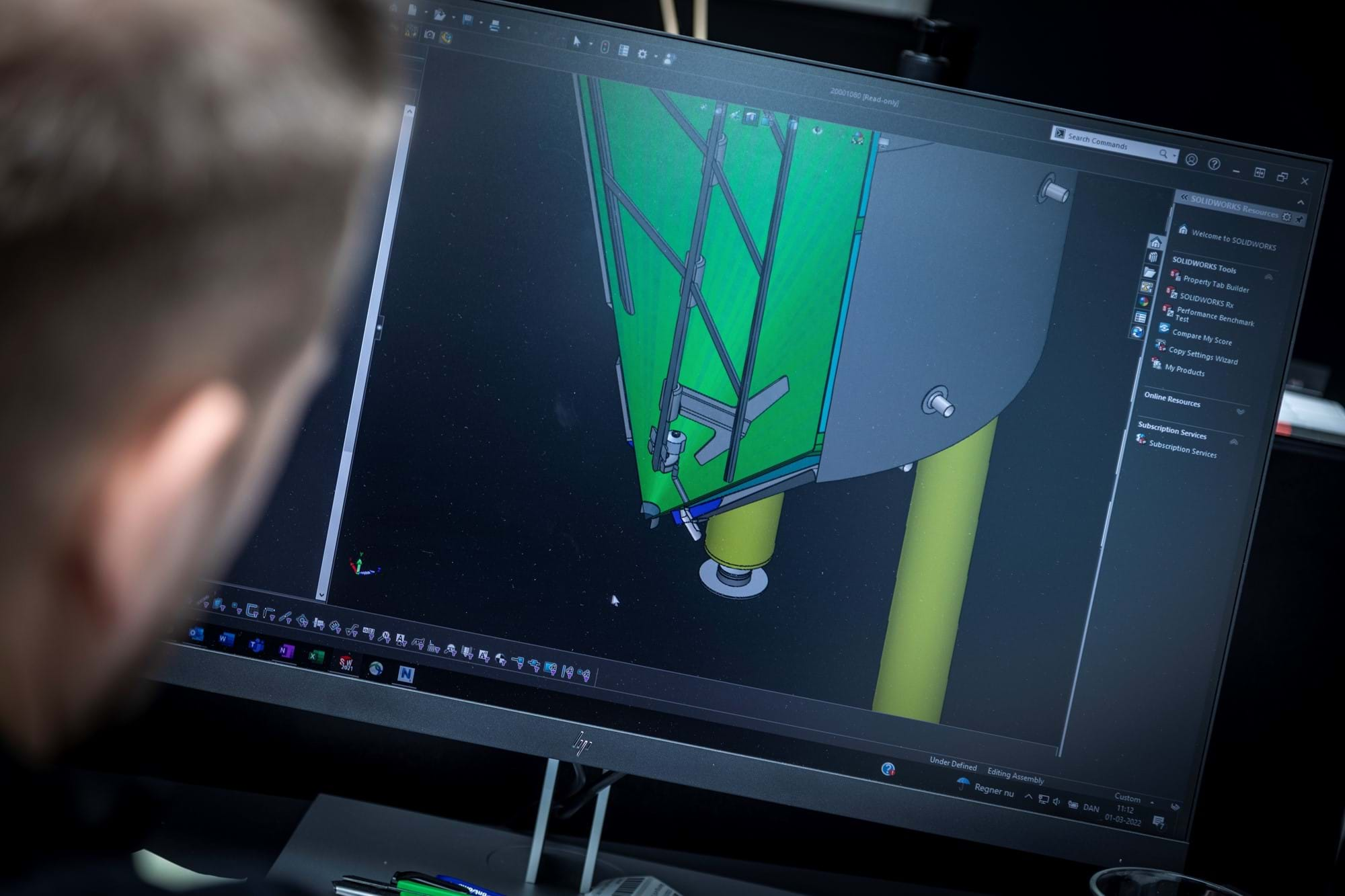

And this doesn't come from standard solutions.

Our products are designed to be as flexible as possible, ensuring a perfect fit for the unique needs of each client. This approach guarantees adaptability and the ability to accommodate future production demands.